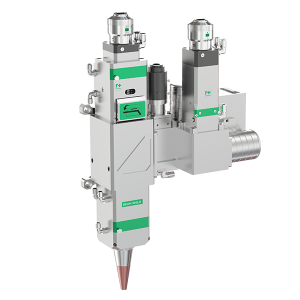

Vikzion Raytools BG06U 6000W Galvanometer Laser Welding Head

Product Features:

- High-Power Welding:High-performance imported motors capable of handling high-power galvanometer welding up to 6kW.

- Excellent Welding Quality:Low porosity, high mechanical properties, and high-quality weld surfaces.

- Rich Scanning Patterns:Any machining trajectory can be customized within a plane to meet process requirements, enabling large-scale machining. The F-theta lens enables focusing, rapid scanning, and fast jumps.

- Rich Expansion Modules:Extensible modules such as temperature sensors, seam tracking, and positioning facilitate automated welding. Welding process detection modules and weld pool temperature detection modules can be added for real-time monitoring of welding quality.

- Efficient Water Cooling:Integrated circulating water cooling ensures long-term, stable operation at high power levels.

- Highly dustproof.:Reliable sealing design extends service life.

1.Product Introduction

The BG06U is a high-power galvanometer laser welding head suitable for remote scanning welding scenarios below 6000W. It features a standard XY2-100 digital galvanometer input and a high-precision galvanometer motor. It can customize any processing trajectory within the welding plane according to process requirements, enabling large-scale processing. It boasts high welding consistency for highly reflective materials, a wide scanning width, and fast welding speeds. It can be combined with visual positioning, weld seam monitoring, and other functions, making it widely used in new energy battery manufacturing.

2.Technical parameters

Laser wavelength | 1064nm |

Fiber optic interfaces | QBH (standard), QD, LLK-B, LLK-D |

Clear aperture | 30mm |

Collimation focal length | 100mm, 125mm, 150mm |

Focus focal length | 330mm, 420mm |

Scanning area | 180x180mm, 200x200mm |

Protective lens | Φ37mmx1.6mm (collimation) |

CCD connection module | Standard C/CS interface |

3.Product advantages

①High-Power Welding

High-performance imported motors capable of handling high-power galvanometer welding up to 6kW.

②Excellent Welding Quality

Low porosity, high mechanical properties, and high-quality weld surfaces.

③Rich Scanning Patterns

Any machining trajectory can be customized within a plane to meet process requirements, enabling large-scale machining. The F-theta lens enables focusing, rapid scanning, and fast jumps.

④Rich Expansion Modules

Extensible modules such as temperature sensors, seam tracking, and positioning facilitate automated welding. Welding process detection modules and weld pool temperature detection modules can be added for real-time monitoring of welding quality.

⑤Efficient Water Cooling

Integrated circulating water cooling ensures long-term, stable operation at high power levels.

⑥Highly dustproof.

Reliable sealing design extends service life.