What are the factors that affect the smoothness of laser cutting edges?

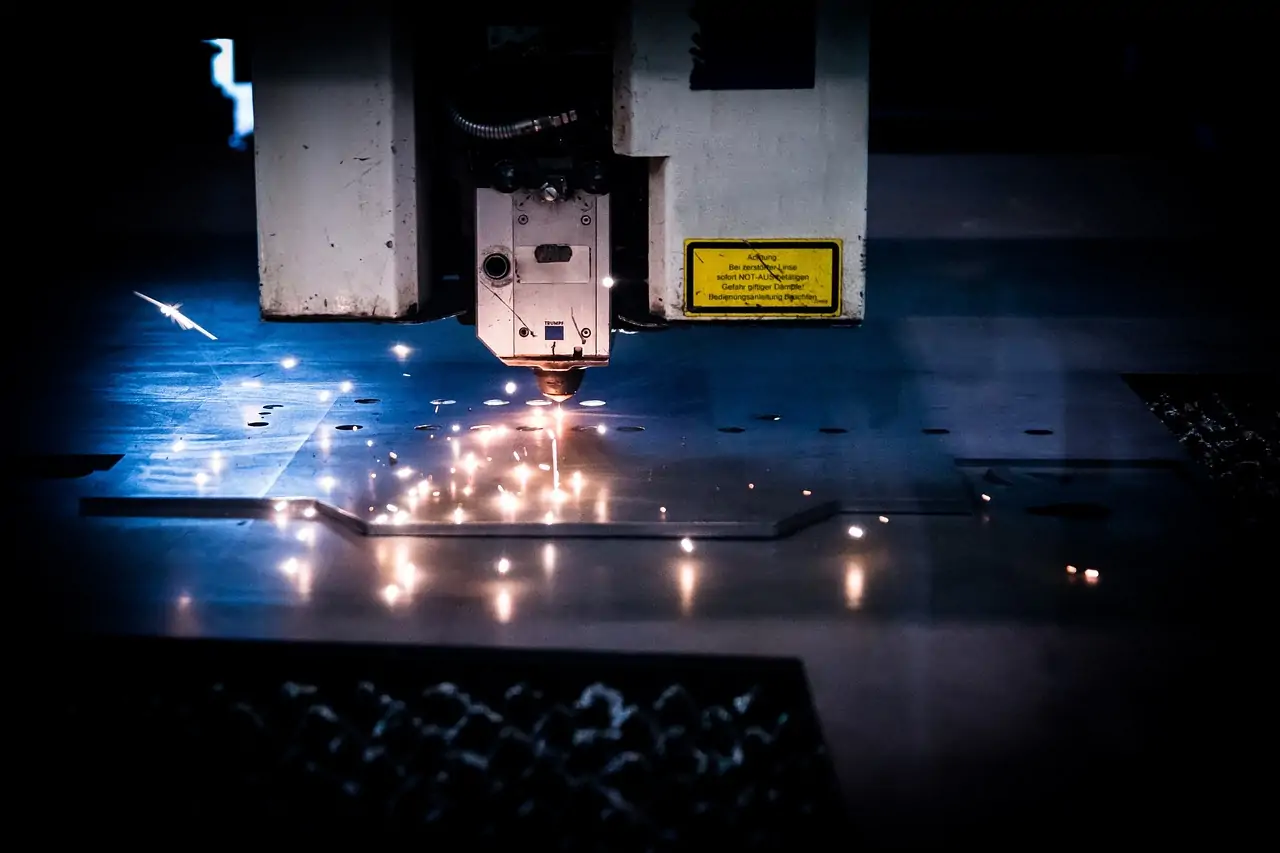

The golden ratio of power and speed Too much power with too-slow speed causes over-melting and dross; insufficient power or

The golden ratio of power and speed Too much power with too-slow speed causes over-melting and dross; insufficient power or

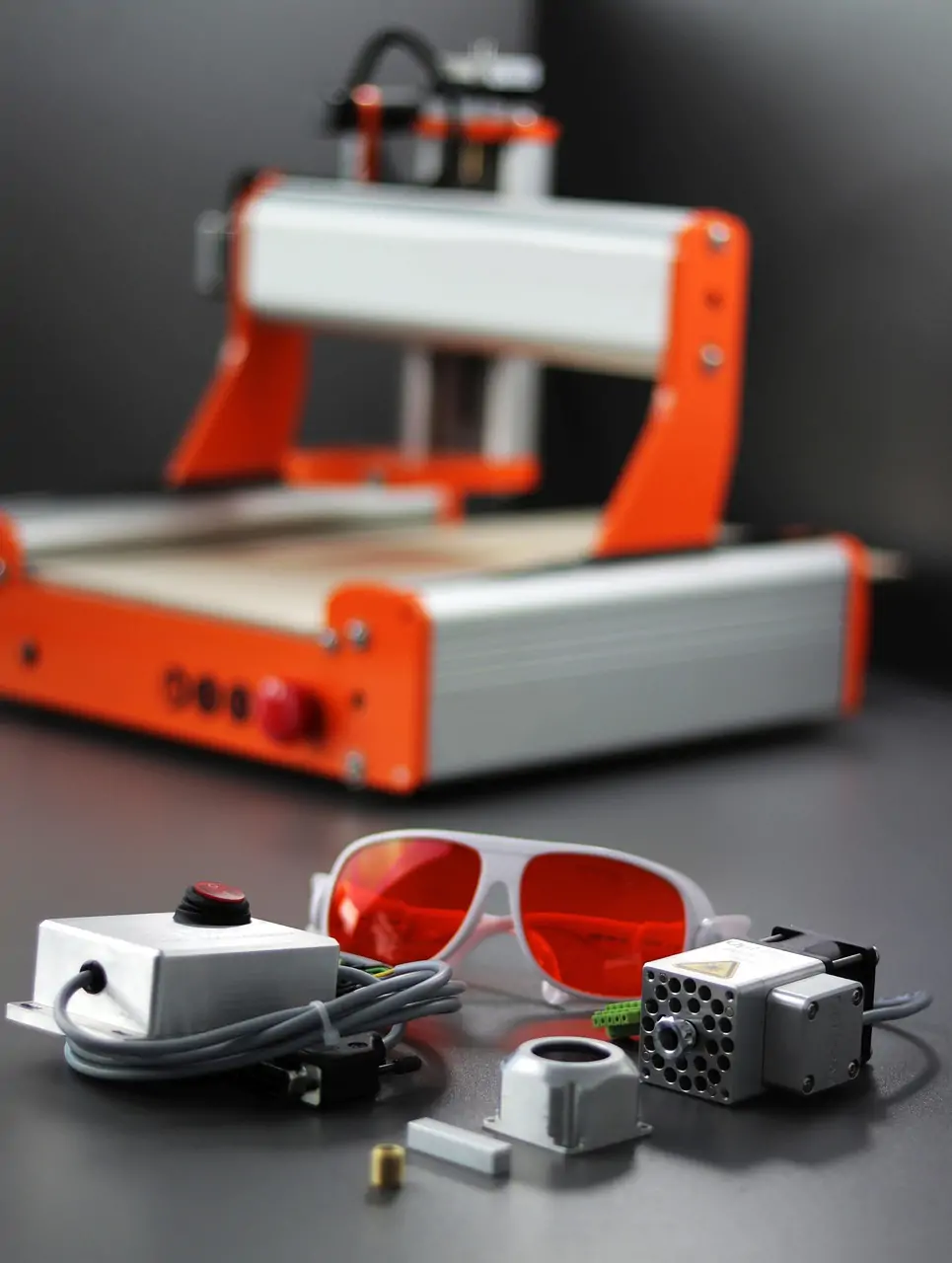

Daily Quick Checks – Ten minutes for peace of mind Before power-on, eyeball three items: ① protective lens clean and

Safety First – Protect People, Then the Machine Laser light is Class-4 radiation; direct or reflected beams can burn retinas

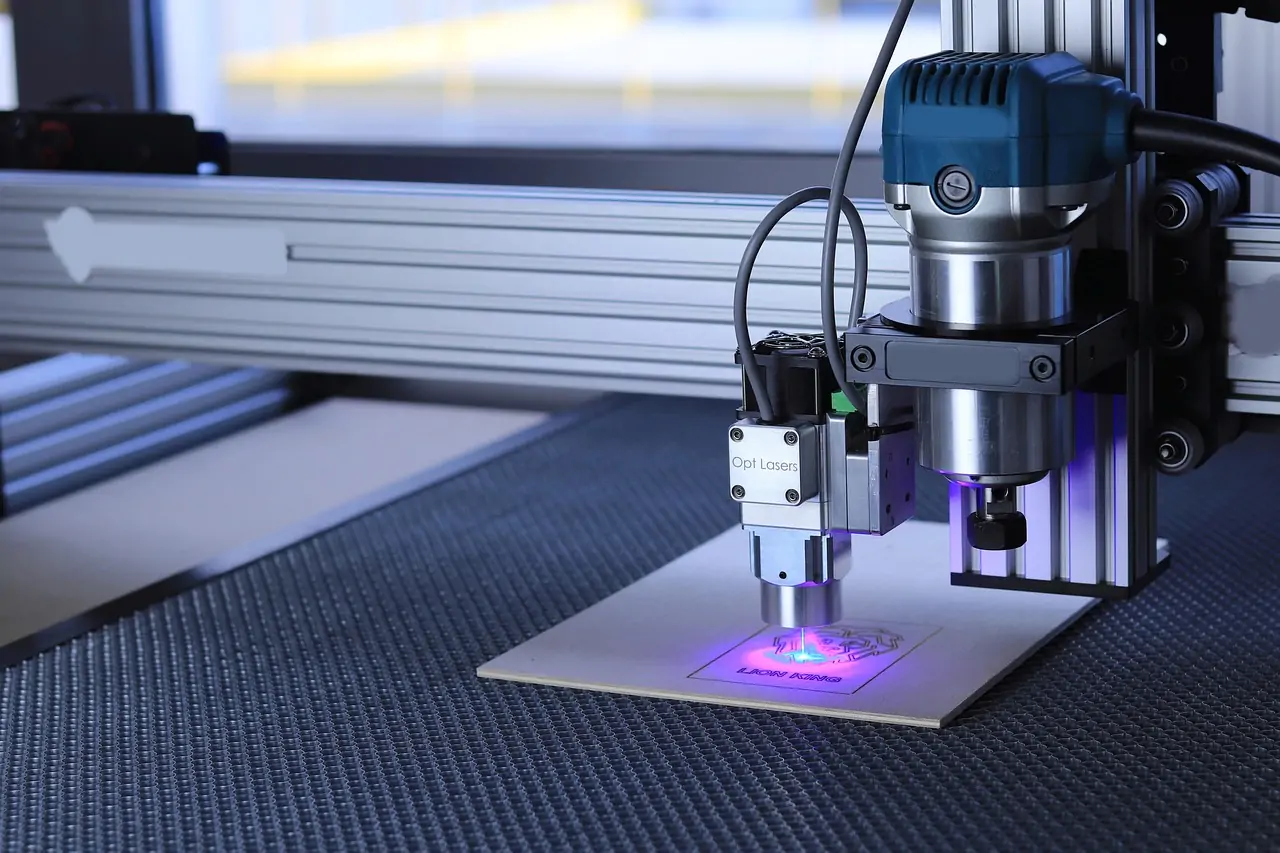

Accuracy & Surface Finish Laser spot sizes of 25–75 µm deliver positioning accuracy of ±0.01 mm and cut-edge roughness Ra

Micron-level precision The laser spot can be focused down to 25 µm—one-third the width of a human hair. With CNC

Metals From stainless-steel sinks to titanium aircraft skins, lasers excel at cutting metals. A 500 W fiber laser can vaporize