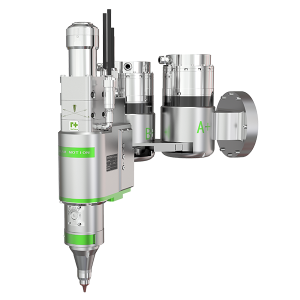

Vikzion Raytools BM109 1500W automatic focusing cutting head

Product Features:

- Multiple protective lenses:3 protective lenses for efficient protection of collimating and focusing lenses

- Highly dustproof:IP65 dustproof rating, patent protected mirror seat cover, dust-proof without dead corners

- Rapid perforation and high-speed cutting:16mm low carbon steel, perforation time<6 seconds, cutting speed 0.6m/min

- Durable and long-lasting:2-way optical water cooling effectively extends the continuous working time

1.Product Introduction

The BM109 series is an automatic focusing cutting head. The product is equipped with an external servo motor and a built-in drive unit, which drives the focusing lens to automatically change its position within a range of about 17mm through a linear mechanism. Users can set continuous focusing through the program to achieve rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. Equipped with QBH interface and fiber laser; The optimized design of optics and water cooling enables the laser head to operate stably for a long time at low to medium power.

2.Technical parameters

Automatic focusing range | +8mm~-9mm |

Automatic focusing speed | ≤6m/min |

Automatic focusing acceleration | ≤10m/s2 |

Automatic focusing accuracy | 50μm |

fiber optic interface | QBH, QD |

Optical aperture | 26mm |

Collimator focal length | 100mm |

Focal length of focusing lens | 125mm,150mm |

Nozzle specifications | Flat:D32*M14, 3D:D15*M8 |

Gas pressure | ≤25bar |

weight | About 3kg |

3.Product advantages

① Multiple protective lenses

3 protective lenses for efficient protection of collimating and focusing lenses

②Highly dustproof

IP65 dustproof rating, patent protected mirror seat cover, dust-proof without dead corners

③Rapid perforation and high-speed cutting

16mm low carbon steel, perforation time<6 seconds, cutting speed 0.6m/min

④Durable and long-lasting

2-way optical water cooling effectively extends the continuous working time