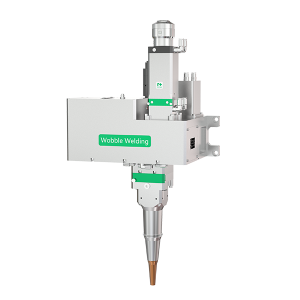

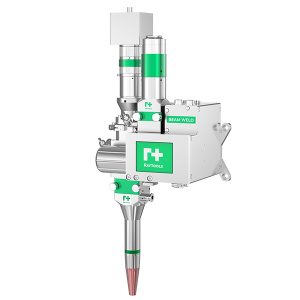

Vikzion Raytools BG04K/BG06K Galvanometer Laser Welding Head

Product Features:

- Process Features:Fast welding speed, rich scanning patterns, and a large working range

- Optimized Design:Internal sealing for efficient dust protection, dual-shield air knife design for slag protection

- Efficient water cooling:Integrated circulating water cooling ensures more stable and reliable operation

- Comprehensive expansion modules:CCD monitoring and visual positioning, compatible with welding process detection modules and weld pool temperature detection modules for real-time monitoring of welding quality

- Excellent welding results:Optimized optical design for high-speed, high-quality welds

- Alarm feedback:Power supply undervoltage and motor abnormality alarm feedback

1.Product Introduction

The BG04K/BG06K is a galvanometer-type laser welding head suitable for remote scanning welding scenarios below 4000W/6000W. It features a standard XY2-100 digital galvanometer input and a high-precision galvanometer motor. It can customize any processing trajectory within the welding plane according to process requirements, enabling large-scale processing. It has high welding consistency on high-reflective materials, a wide scanning area, and fast welding speeds. It can be combined with functions such as visual positioning and weld monitoring, and is widely used in new energy battery manufacturing.

2.Technical parameters

Fiber Optic Interface | QBH |

Applicable Wavelength | 1070 ± 10nm |

Laser Power | 4000W |

Clear Aperture | ⌀30mm |

Collimation Focal Length | 100mm/125mm/150mm |

Field Lens Focal Length | 330mm/Customizable |

Oscillating Control Protocol | XY2-100 |

Power Supply | ±15V5A (150W) |

Welding Format | 150mm x 150mm (330mm Field Lens), Customizable |

Maximum Welding Speed | 3000mm/s |

Operating Temperature | 15℃ to 35℃ |

Laser Head Weight | Approximately 10kg |

Alarm Signal | Drive Abnormality Alarm (Indicator Light) |

Extended Functions | CCD Monitoring, Vision Positioning, etc. |

3.Product advantages

①Process Features

Fast welding speed, rich scanning patterns, and a large working range

②Optimized Design

Internal sealing for efficient dust protection, dual-shield air knife design for slag protection

③Efficient water cooling

Integrated circulating water cooling ensures more stable and reliable operation

④Comprehensive expansion modules

CCD monitoring and visual positioning, compatible with welding process detection modules and weld pool temperature detection modules for real-time monitoring of welding quality

⑤Excellent welding results

Optimized optical design for high-speed, high-quality welds

⑥Alarm feedback

Power supply undervoltage and motor abnormality alarm feedback