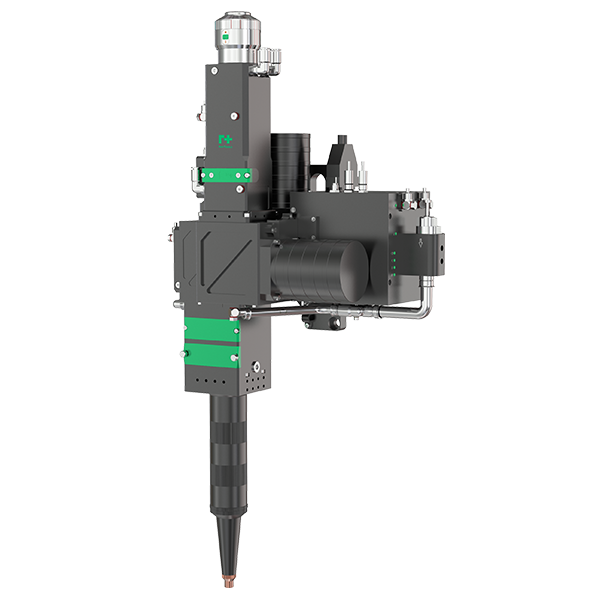

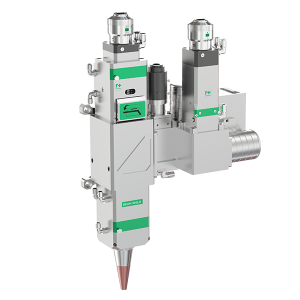

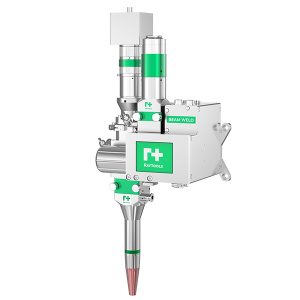

Vikzion Raytools BF12K/BF20K Swinging Laser Welding Head

Product Features:

- High-Power Welding:Suitable for 20kW high-power welding, it can quickly penetrate materials, meeting the needs of efficient welding of thick plates and high-strength materials.

- Welding Process Visualization:Equipped with a CCD monitoring interface, it can capture images of the weld pool during welding.

- Temperature Monitoring:Built-in four-channel lens temperature monitoring with alarm output enables real-time monitoring of lens temperature during welding, providing timely warnings of lens anomalies to prevent potential equipment damage and production interruptions.

- Optimized Optics:The optimized high-power collimation solution enables the BF20K to provide excellent beam quality, effectively ensuring weld consistency.

- High-Performance Motor:The advanced galvanometer oscillation system precisely controls the oscillation pattern, ensuring uniform and consistent welds.

- Efficient Cooling:Multi-channel lens water cooling and galvanometer lens air cooling significantly improve weld reliability.

- Rich Scanning Patterns:Supports continuous oscillation welding with a variety of patterns, and can flexibly adjust oscillation parameters as needed.

1.Product Introduction

The BF12K oscillating welding head is suitable for high-power welding. It uses scanning to increase weld width, reduce porosity, and improve surface quality. It features a wide range of scanning patterns, including support for circular, linear, C-shaped, and S-shaped scanning welding. It also offers a wide range of module options, including a side-axis laser source for TCP calibration, a side-axis blue spot light source for CCD image illumination, a position sensor for position tracking, a temperature sensor for equal penetration welding, and a side-axis wire feeder for filler wire welding, facilitating automated welding. An optimized optical design enables high-speed, high-quality, high-power laser welding. A smooth and efficient fluid structure ensures optimal weld pool protection. The collimation, focusing, and galvanometer mirrors are all water- or air-cooled, ensuring long-term stable operation and extended service life.

2.Technical parameters

Fiber Optic Interface | QBH/LOE |

Applicable Wavelength | 1064nm |

Laser Power | ≤12000W |

Clear Aperture | 34mm |

Collimation Focal Length | 100mm, 150mm |

Focus Focal Length | 300mm, 350mm |

Oscillation Range | X-axis: 0-5mm; Y-axis: 0-5mm |

Oscillation Frequency | 0-500Hz |

Weight | Approximately 9kg |

3.Product advantages

①High-Power Welding

Suitable for 20kW high-power welding, it can quickly penetrate materials, meeting the needs of efficient welding of thick plates and high-strength materials.

②Welding Process Visualization

Equipped with a CCD monitoring interface, it can capture images of the weld pool during welding.

③Temperature Monitoring

Built-in four-channel lens temperature monitoring with alarm output enables real-time monitoring of lens temperature during welding, providing timely warnings of lens anomalies to prevent potential equipment damage and production interruptions.

④Optimized Optics

The optimized high-power collimation solution enables the BF20K to provide excellent beam quality, effectively ensuring weld consistency.

⑤High-Performance Motor

The advanced galvanometer oscillation system precisely controls the oscillation pattern, ensuring uniform and consistent welds.

⑥Efficient Cooling

Multi-channel lens water cooling and galvanometer lens air cooling significantly improve weld reliability.

⑦Rich Scanning Patterns

Supports continuous oscillation welding with a variety of patterns, and can flexibly adjust oscillation parameters as needed.