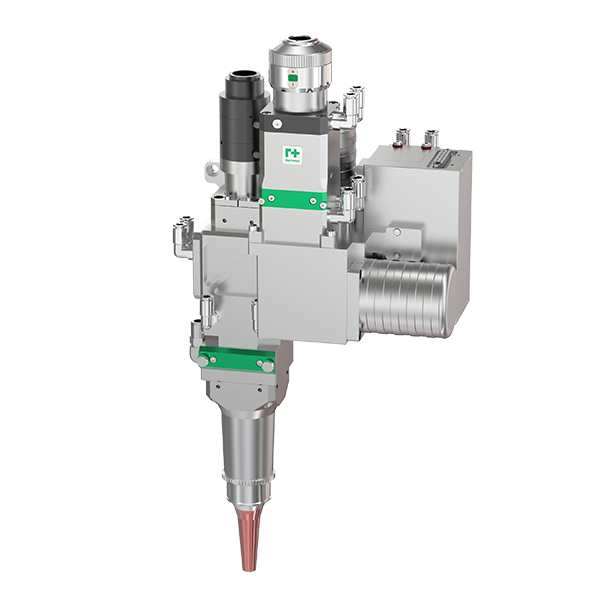

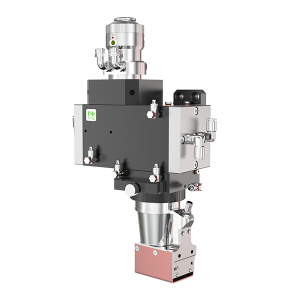

Vikzion Raytools BF04K 4000W Swinging Laser Welding Head

Product Features:

- High Power Handling:Maximum power handling capacity reaches 4kW, meeting the demands of the medium- and high-power welding market.

- Process Advantages:Increased weld width; increased gap adaptability; reduced weld defects; excellent forming results.

- Ease of Automation:Expandable seam tracking or positioning functions facilitate robotic automation integration. Compatible with welding process detection modules and weld pool temperature detection modules for real-time monitoring of weld quality.

- High-Quality Airflow Design:The coaxial and side-axis protection nozzles and air knives utilize a smooth and efficient flow structure, ensuring excellent weld pool protection and slag removal.

- High Scanning Frequency and Multiple Motion Paths:Optimized optical structure and motion mechanism, diverse stirring paths, and high stirring frequencies meet the diverse needs of high-speed stir welding.

1.Product Introduction

BF04K is an oscillating laser welding head suitable for oscillating laser welding scenarios below 4000W. It uses dual-motor oscillation to make the oscillation mode more diverse. It uses standard XY2-100 digital galvanometer input for control and is equipped with a high-performance galvanometer motor. It has higher scanning accuracy and richer custom scanning parameters. It can be equipped with a high-definition CCD to monitor the weld condition in real time, making it suitable for a wider range of scenarios.

2.Technical parameters

Power level | ≤4000W |

Laser wavelength | 1064nm |

Scanning speed | ≤2800mm/s |

Clear aperture | 30mm |

Weight | approximately 5.8kg |

3.Product advantages

①High Power Handling

Maximum power handling capacity reaches 4kW, meeting the demands of the medium- and high-power welding market.

②Process Advantages

Increased weld width; increased gap adaptability; reduced weld defects; excellent forming results.

③Ease of Automation

Expandable seam tracking or positioning functions facilitate robotic automation integration. Compatible with welding process detection modules and weld pool temperature detection modules for real-time monitoring of weld quality.

④High-Quality Airflow Design

The coaxial and side-axis protection nozzles and air knives utilize a smooth and efficient flow structure, ensuring excellent weld pool protection and slag removal.

⑤High Scanning Frequency and Multiple Motion Paths

Optimized optical structure and motion mechanism, diverse stirring paths, and high stirring frequencies meet the diverse needs of high-speed stir welding.