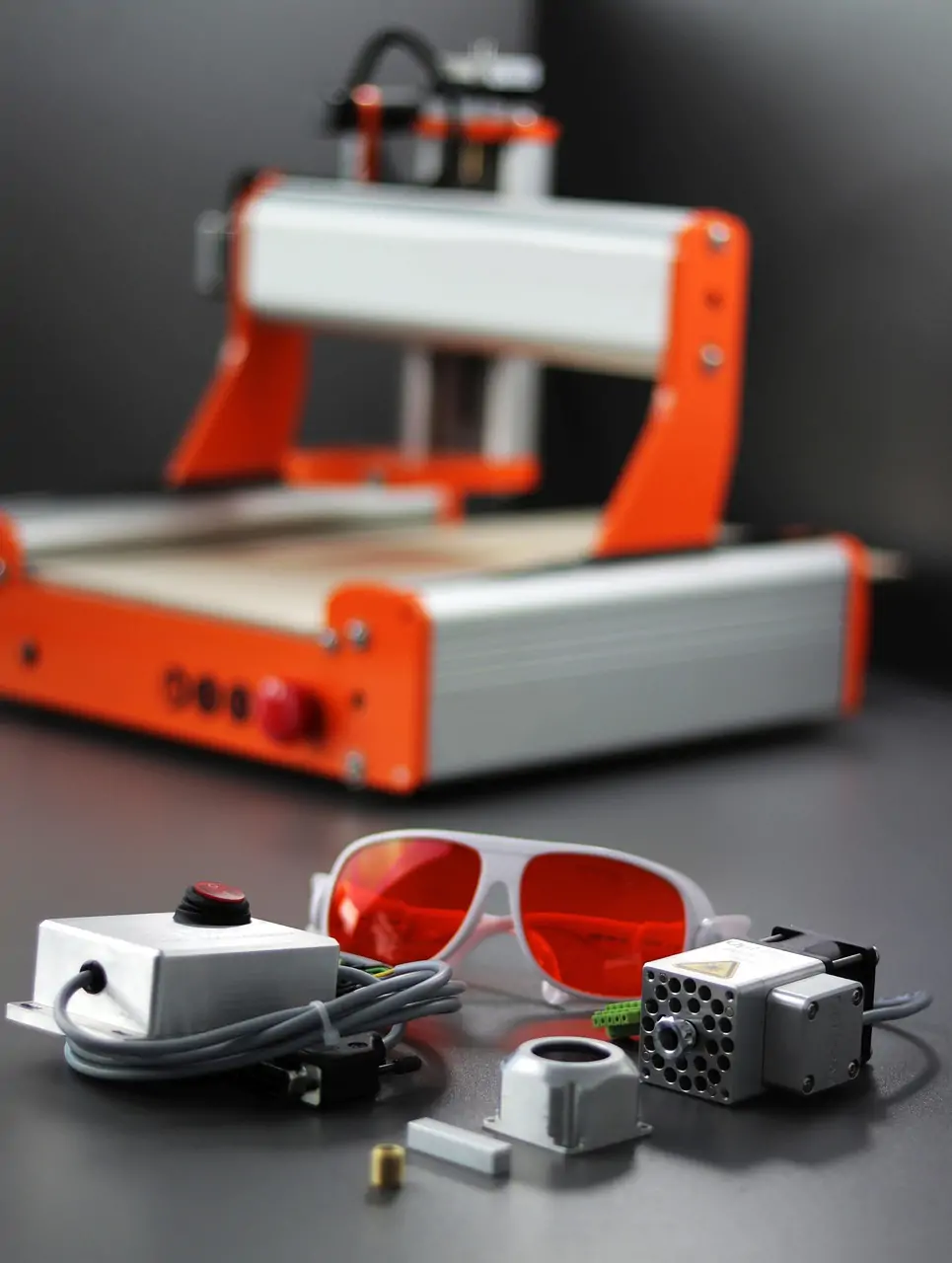

Safety First – Protect People, Then the Machine

Laser light is Class-4 radiation; direct or reflected beams can burn retinas instantly. Always wear wavelength-matched safety goggles, interlock the safety door, and keep a mushroom-head E-stop within arm’s reach. Plasma glare and molten spatter during metal cutting call for flame-resistant gloves and face shields.

Know Your Material – Not Every Sheet Belongs on the Bed

PVC, chlorinated plastics, or fluoropolymer-coated sheets release toxic gases when heated and must never be processed. Highly reflective copper, aluminum, and brass require higher power and slower speeds, or reflected light can damage the laser source. Check the material certificate and the machine’s compatibility list before loading.

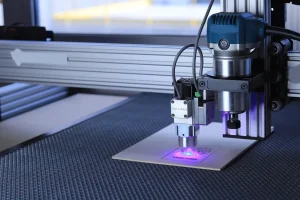

Parameter Tuning – Power, Speed, Gas Pressure

Too much power on thin sheets chars the edge; too much speed on thick plates leaves dross. Run test cuts on scrap until the kerf is clean and barely straw-colored, then lock in the settings. Adjust assist-gas pressure with thickness: nitrogen for stainless to prevent oxidation, oxygen for carbon steel to boost combustion.

Daily Maintenance – Clean Optics, Sharp Focus

Mirrors, protective lenses, and nozzles should be wiped with lint-free cloth and isopropanol every morning. Replace immediately if black spots or scratches appear—otherwise focal shift will scrap a whole batch. Grease ball screws and linear guides every 100 machine-hours to keep abrasive dust from ruining accuracy.

Fume & Dust Extraction – Invisible Hazards Kill

Cutting fumes carry ultrafine metal particles and VOCs linked to pneumoconiosis. Maintain extractor airflow at or above the rated value and change filters when the differential-pressure alarm sounds. For aluminum or magnesium dust, add spark arrestors to eliminate explosion risk. A clean machine makes healthy operators and consistent cuts.