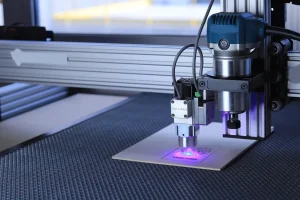

The golden ratio of power and speed

Too much power with too-slow speed causes over-melting and dross; insufficient power or excessive speed leaves jagged edges or incomplete cuts. The rule of thumb: raise speed as high as possible while still achieving full penetration, yielding fine striations without burn. Each additional 1 kW allows roughly 30 % faster feed on 6 mm stainless.

Assist-gas type and pressure

Oxygen speeds carbon-steel cutting but darkens the edge; nitrogen produces bright, oxide-free stainless cuts yet demands 1.0–1.5 MPa to blow molten slag away. Too-low pressure leaves wavy striations; too-high creates turbulent flow. Listen for a steady, crisp hiss—that’s the sweet spot.

Focal position and beam quality

Placing the focal point ~1/3 of the plate thickness below the surface yields the narrowest kerf and lowest roughness. A ±1 mm shift can raise Ra from 3 µm to 8 µm. Periodically check beam circularity and power density with a power meter and beam profiler to spot dirty optics or collimation drift early.

Material thickness and surface condition

Roughness roughly doubles with each doubling of thickness. Oxide scale and oil absorb laser energy unevenly, producing pits. Wipe plates with acetone and ensure flatness within ±0.5 mm before cutting to noticeably improve edge quality.

Treat power, speed, gas pressure, focus, and material state as one interactive system. Start with single-factor tests, then use orthogonal optimization to keep edge roughness on common metals at Ra ≤ 5 µm.